PET Heat Transfer Film Manufacturer and Supplier

Professional PET Heat Transfer Film for Superior Print Quality

With more than 10 years of experience

Professional PET Heat Transfer Film Manufacturer

Our Products

Why Choose Us

Product Effect Display

FAQs

Online

You can text online messages to us, leaving your name and contact information. Our service team will reply to you in short time for further negotiation.

Phone

Call us and our customer service representatives are ready to help you and answer any questions. For quicker processing, have the item number of the product you wish to purchase ready when you call.

Send your inquiry detail or purchase order by mail info@heattransferfilms.com.

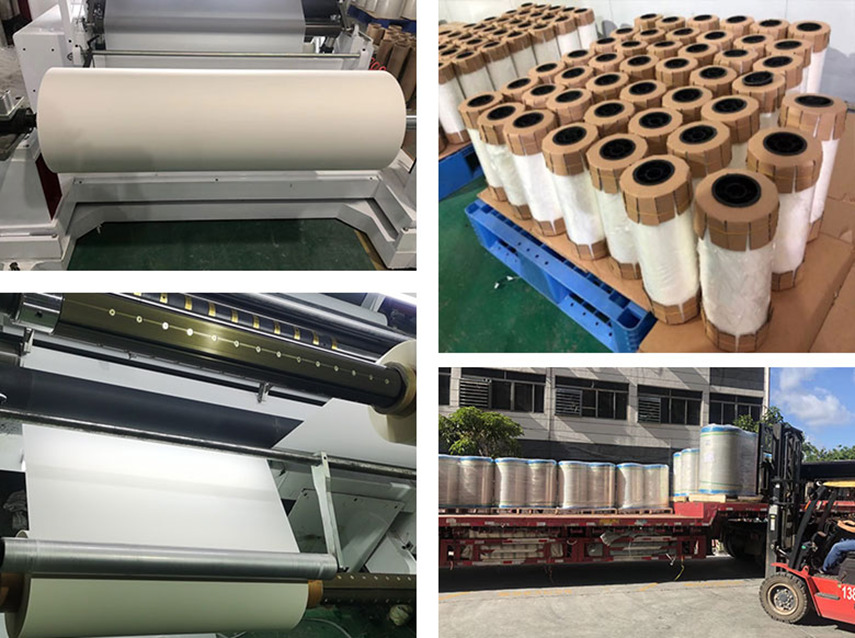

All products are made with first-class raw material, our all production lines are automatic and free of dust level.

Before production, our quality team will check our raw material carefully, guarantee no any issue then go on the production, after that we will recheck the finished products.

Before shipment, our quality test team checks every piece of our goods again, 3 times checking to guarantee our all shipment goods are high quality and standard.

Before you send the order, we will arrange the sample for your test, we promise all order's quality are kept the same as the sample quality which is confirmed by our customers.

As normally, we ship the goods by sea or by air depending on the good's weight, quantity and customer request.

The degree of export packing required moisture protection, fixed stronger no damage. So we used the first-grade pp film inside packing, then pack in 5mm thick cardboard. At last put on non-fumigation pallets.

Secondly, our all warehouse person is full experienced in export goods packing, they will save the package volume by different specification mixed packing to save your freight cost.

24/7 online customer support. After-sales service stays in touch with the customers even after the deal. Whether the customer is happy with the products or not? By each other good communication, our customers will believe in our brand. We take it as an important part of our company culture.

Create a section in the website where the customers can feedback anytime. Our customer service team should take prompt action on the customer's queries. The problems must be resolved immediately.

We agree to replace the products if found faulty also offer variable warranty policies to customers.

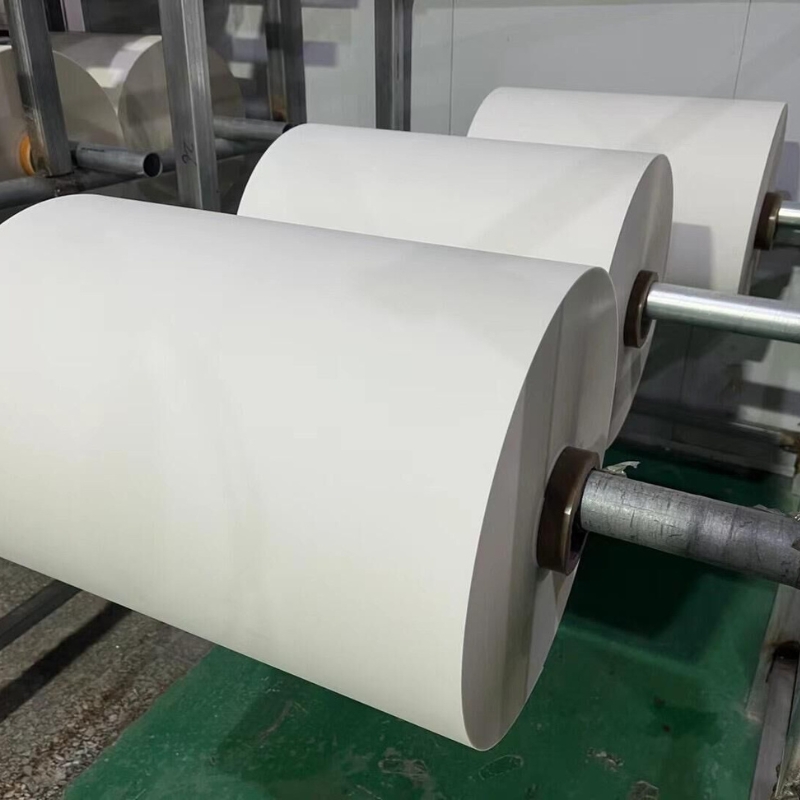

Production Capacity and Inventory

QianTai is a professional manufacturer of PET Transfer Release Film and transfer media in China with a history of more than 10 years. QianTai has a complete set of production equipment and pollution treatment equipment, with strong production capacity and ability to digest orders. And to ensure green production, raw materials are non-toxic and harmless, the production process is environmentally friendly, and help circular economy. And we have a certain stock of inventory, which can meet the urgent needs of customers in a timely manner.

Quality Inspection

-

Responsible for the operation of the quality management system to ensure the high quality of products.

-

Designate inspection standards, clarify inspection methods, inspection procedures and non-performing matters.

-

Responsible for the collection, summary and analysis of customer satisfaction information, and take measures to improve and perfect the quality work.

-

Ensure product quality can meet customer requirements.

Introduction to PET Heat Transfer Film

PET heat transfer film is a heat transfer medium based on polyester film, widely used in garment printing, pattern transfer, packaging surface decoration, and industrial labeling. Compared with traditional transfer materials, PET heat transfer film offers significant advantages in dimensional stability, high-temperature resistance, and surface flatness, making it suitable for applications requiring high precision and consistent finished products.

PET polyester heat transfer film, also known as PET transfer film or PET release film, involves applying several coating release layers on a PET film substrate. Commonly available in thicknesses ranging from 75u to 120u, this film features both hot and cold peeling options and a matte surface. It undergoes anti-static and anti-scratch treatments to enhance adsorption and adhesion properties.

The operational heat transfer temperature ranges from 130-160 °C, achieving a complete transfer effect. The film's surface may feel slightly sticky when heated but becomes smooth upon cooling. Its back-coated anti-adhesive layer prevents damage from adhesion during long-distance transport, thus saving on transportation costs and is suitable for fine pattern to block color printing achieving ideal results with 175-210# screen printing screens.

This film has passed the BV test and meets Oeko-Tex Standard 100 certification, demonstrating its resistance to high temperatures, washing, and weather conditions. Made from polyurethane, it remains non-sticky at 60 degrees and does not harden or become brittle at temperatures as low as -30 degrees.

Analysis of Key Parameters of PET Heat Transfer Film

Choosing the correct specifications is crucial for ensuring stable transfer printing results. The following parameters directly affect your production efficiency and product quality:

Thickness:

-

Common range: 50μm – 125μm

-

Thinner (50–75μm): Good flexibility, suitable for curved or soft substrates

-

Medium thickness (75–100μm): General purpose, suitable for most garment and label transfers

-

Thicker (100μm+): Higher strength and stability, suitable for high-precision or industrial applications

Heat Resistance:

-

Standard operating temperature: 130–180°C

-

High-temperature resistant model: Supports higher heat pressing temperatures, suitable for special inks or applications requiring high adhesion.

Coating:

-

General-purpose coating: Suitable for water-based, solvent-based, and UV inks

-

High-adhesion coating: Used for difficult-to-adhere substrates such as leather and synthetic materials

-

Peelable / Cold peel / Hot peel: Affects the processing method and the appearance of the finished product

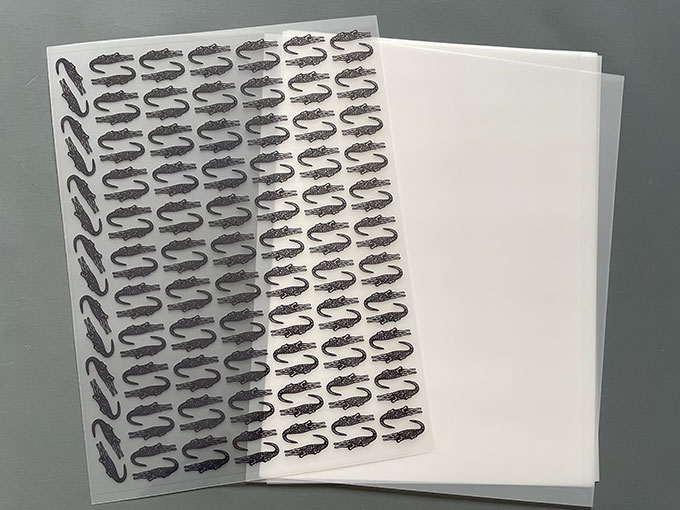

Advantages of QIANTAI PET Heat Transfer Film for Screen Printing

QIANTAI is a leading manufacturer of hot peel PET transfer release film, specializing in high-quality plastisol transfer paper. Recognized for their robust industry presence in China, QIANTAI offers a diverse range of plastisol transfer papers designed for superior adhesion, vibrant colors, and durability.

Committed to customer satisfaction, QIANTAI provides exceptional service and expert guidance throughout the purchasing process, ensuring a seamless experience for clients needing top-notch screen printing solutions.

Anti-Static Coating: Our films undergo a specialized anti-static treatment, ensuring no excess powder sticks to non-image areas during the DTF process. This results in clean, sharp edges and reduces production waste.

High Ink Absorption: The multi-layer coating technology allows for high-density ink loading without bleeding. Achieve 95%+ color restoration with photorealistic clarity and vibrant gradients.

Outstanding Washability: Tested to withstand over 50 industrial wash cycles. The patterns remain soft, flexible, and free from cracking or fading even after repeated stretching.

Flexible Peel Options: Available in True Hot Peel (peel instantly for high efficiency) and Cold Peel (for ultra-matte, delicate textures).

Benefits of Using PET Heat Transfer Film Paper for Screen Printing

PET heat transfer film paper, also known as hot peel plastisol transfer paper film, offers several benefits:

- Excellent heat resistance: Can withstand high temperatures without warping, ideal for transferring plastisol inks.

- Enhanced print quality: Provides a smooth surface for detailed printing, ensuring uniform ink adhesion for sharp, vibrant prints.

- Easy release of transferred design: The hot peel feature allows for quick paper removal post-transfer, leaving a clean design.

- Versatile compatibility: Works with a variety of fabric types and colors, suitable for diverse screen printing projects.

Standard Operating Procedure

This operating procedure is based on various application scenarios including garment printing, label transfer, and industrial surface decoration, and conforms to the process standards of mainstream heat press equipment. Correctly following these steps will significantly improve transfer durability, image clarity, and production stability.

Step1: Surface Preparation

Before transfer printing, it is essential to ensure that the substrate surface is clean, dry, and smooth, as this is the primary factor affecting adhesion.

Key operating points:

-

Remove dust, oil, moisture, silicone oil residue, or release agents from the substrate surface.

-

For fabric materials (such as cotton, polyester, and blends): It is recommended to perform a 2–3 second pre-press to remove moisture and wrinkles.

-

For leather, synthetic materials, or coated materials: Gently wipe the surface with a lint-free cloth and alcohol to ensure there is no oil film.

Quality control standards:

-

No visible particles on the surface

-

No obvious moisture or oil stains

-

Smoothness meets the requirements for uniform heat press contact.

Step2: Printing & Drying

The pattern is printed onto the coated surface of the PET heat transfer film using a suitable ink system.

Ink Compatibility:

-

Solvent-based inks

-

UV inks

-

Water-based inks (requires complete drying)

Operating Points:

-

Ensure the printed pattern has uniform color and sharp edges.

-

The ink must be completely dry before heat pressing; otherwise, it may cause: Bubbles, Pattern spreading, Poor adhesion after transfer.

Recommended Standards:

-

Air drying at room temperature for ≥ 10–30 minutes (depending on ink type)

-

Or use low-temperature drying equipment to accelerate drying.

Step3: Positioning

Place the printed PET heat transfer film onto the target position of the substrate, ensuring precise positioning.

Key operating points:

-

The printed side should be in direct contact with the substrate, with the film facing outwards.

-

Secure with high-temperature resistant tape or a positioning frame to prevent displacement during heat pressing.

-

For multi-color or multi-layer patterns, pre-alignment is required to confirm the overall layout.

Quality control standards:

-

The pattern edges should be aligned with the positioning lines on the substrate.

-

No obvious wrinkles or curling of the edges.

Step4: Heat Press Transfer

This is a critical step in determining the final adhesion effect, requiring simultaneous control of three core parameters: temperature, pressure, and time.

1) Temperature Setting

-

Typical range: 140–170°C

-

For high-adhesion or industrial coating models, the temperature can be increased to 180°C (testing required for confirmation).

2) Pressure Setting

-

Medium to high pressure is recommended.

-

Ensure even pressure distribution across the entire pattern area to avoid incomplete transfer in certain areas.

3) Time Control

-

Standard time: 8–15 seconds

-

For thick patterns or multi-layer inks, the time can be extended to 15–20 seconds.

Operating Procedures:

-

The heat press plate should completely cover the pattern area.

-

Avoid repeatedly moving the heat press head to prevent ghosting or stretching deformation.

-

Parameters should be fine-tuned based on the actual pressure distribution for different equipment (flatbed press, roller press, automated equipment).

Step5: Peeling

Based on the coating type of the PET heat transfer film, select the correct peeling method:

Peeling Type:

-

Hot Peel: Peel immediately after heat pressing

-

Cold Peel: Peel after the substrate has cooled to room temperature

Operating Points:

-

Maintain a 180° peeling angle

-

Peel evenly and steadily, avoiding rapid pulling that may cause the edges of the pattern to lift

Quality Standards:

-

No adhesive residue after film peeling

-

The pattern edges are clear and undamaged

Step6: Post-Press(Optional)

To improve washability, abrasion resistance, or industrial adhesion strength, a second heat pressing is recommended.

Instructions:

-

Cover the design surface with a silicone release paper or non-stick film.

-

Heat press again for 3–5 seconds.

-

Maintain the same temperature as the first heat pressing.

Improved results:

-

Enhanced adhesion

-

Smoother surface

-

Increased resistance to friction and washing cycles

Attention Points For PET Heat Transfer Film

During the printing production, avoid scratching or touching the film with sharp objects. Store the PET transfer film in a room that maintains constant temperature and humidity. The shelf life of the film is 1 year from production if the package remains unopened. Post-printing, it is advised to wait 24 hours before washing the fabric.

Choose Professional PET Heat Transfer Film Manufacturers and Suppliers

As the top PET Heat Transfer Film manufacturer in China, our service team has more than ten years of industry experience, they will provide you with a comprehensive PET Heat Transfer Film solution, and work with you between your requirements and costs Find the balance.

Provide pre-sales and after-sales assistance by phone or email, and our service team will provide you with timely support. We will be your reliable long-term partner.

If you have any questions or need customized services, please contact us immediately, we will give the best solution!

Top PET Heat Transfer Film Manufacturer

Contact us today and let our team of experts guide you in choosing the perfect PET heat transfer film for your specific needs.